HQ is a professional source for flexible packaging products. Established in 1973, we are committed to offering customized packaging film for customers involved in pharmaceuticals, food, and electronics. We are especially proficient in the production of high barrier laminated packaging films. According to different types of packaging and performance requirements, HQ can customize various packaging materials, including multi-layer laminates, pre-made pouches, aluminum foil, and cold form aluminum foil.

If you are looking for the most suitable packaging material, you’ve come to the right place. HQ is fully equipped to provide you with customized packaging solutions.

-

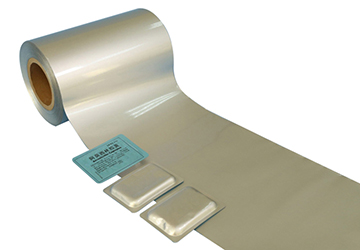

- Cold Formed Alu Alu Foil Cold formed Alu Alu foil is a type of laminated material with superior barrier properties. It features a laminated structure of PA/AL/PVC. The middle layer of aluminum protects against 100% of water vapor, oxygen, UV rays, and is especially suitable for the blister packaging of medicine. Aluminum cold forming foil helps to maintain the stability of medicines and extends their shelf life.

-

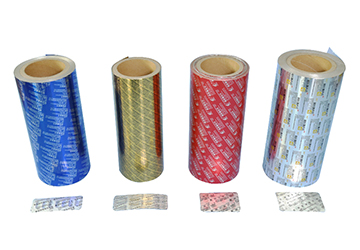

- Cold Form Foil for High Barrier Packaging Aluminum foil offers superior barrier properties to protect packaged contents from oxygen, moisture, and light. It can be used for heat sealing with PVC, PVDC and other plastic hard films, and it can also be used for blister packs.

-

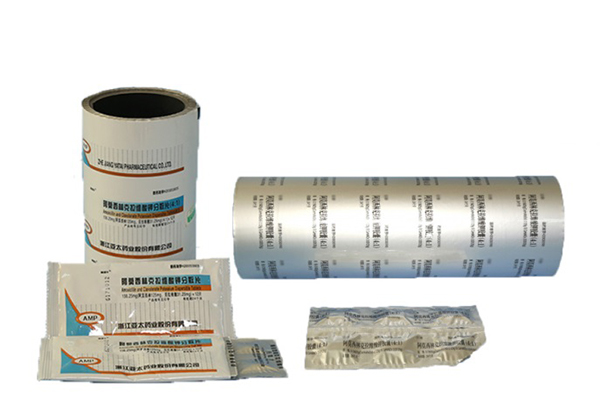

- High Barrier Film Laminations HQ provides high barrier film laminations made of an electrolytic aluminum with a 99.0%-99.97% purity by laminating technology. These laminations significantly improve properties of the overall laminated film, including water and oxygen resistance and light shading. These high barrier film laminations also ensure your product has a better stability and longer shelf life.

-

- Flowpack Film Laminations HQ provides laminated packaging film rolls in a variety of structure, which are used as form-fill-seal films for flow wrapping systems for packaging of a variety of granules and powders. Flow wrapping is also known as fin seal packaging and lap seal packaging, and compared to pre-made pouches, significantly improves production efficiency and decreases production costs.

-

- Sachet Films HQ provides multi-layer films used for packaging pouches for powder, granules, or liquid products, such as medicine, snacks, cheese, dietary supplements, and more. These pouches include packets, four-sided seal pouches, stand up pouches and more. Different pouch shapes feature different applications to meet flexible packaging needs.

-

- Stick Pack Films Stick packs, also known as stick pouches, are widely used for packaging powdered materials, such as dietary supplements, powdered drink mixes, milk powder, instant coffee and more. Compared to a normal sachet, stick pack films save about 40% more materials, which in turn significantly reduces production costs.

-

- Modified Atmosphere Packaging (MAP) Films HQ produces rolls of high-barrier film laminations in a variety of structures for use as modified atmosphere packaging films. As these films feature an outstanding water and oxygen resistance, users can rest assured there is a perfect gas concentration inside every pack, ensuring storage conditions are improved for a longer storage life with less oxidation and product spoiling.

-

- Preformed Pouch According to customer needs. HQ provides finished pouches, including center seal pouches, 3 side seal pouches and other pouch types for use in filling machines to significantly improve the packaging process efficiency.

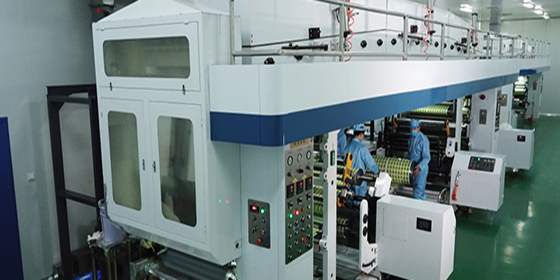

- We own automated production factory As an experienced professional manufacturer of lamination metallized film and pouches, HQ now has a yearly output of laminated films, pouches, and medicinal aluminum foil of 2000 tons, 100 million, and 1000 tons respectively.

- We put high importance on health and safety HQ’s specialty lies in providing high-quality flexible packaging products for global pharmaceutical and food enterprises. To ensure that our products fully satisfy the strictest sterility and hygiene requirements, we built a perfect quality control system according to ISO9001:2015 standards. The cleanliness of our workshops are up to degree D.

Get in touch now Contact

Add.: No. 8, Area B, Yangjian Industry Zone, Wuxi City, Jiangsu Province

Fax.: +86-510-88331663